Get to know how an Aluminum Casting Company helps deliver quality at scale

Wiki Article

The Evolution of Light Weight Aluminum Spreading Techniques

Over the decades, different innovative techniques have changed light weight aluminum spreading, significantly boosting its performance and accuracy. The evolution began with typical sand spreading methods, which, while effective, frequently caused inconsistencies in surface coating and dimensional accuracy. The introduction of die spreading in the mid-20th century enabled faster manufacturing rates and boosted quality, as molten aluminum was compelled into molds under high stress, decreasing porosity and enhancing information.More innovations consisted of investment spreading, which supplied also intricate layouts and better tolerances. The development of computer system numerical control (CNC) innovation likewise revolutionized mold style, allowing producers to develop complicated geometries with exceptional accuracy. Today, additive manufacturing techniques, such as 3D printing for creating molds, are on the surge, enabling quick prototyping and minimized preparations. In general, these developments have considerably influenced the light weight aluminum casting process, accommodating a broader range of commercial applications.

Advantages of Aluminum in Production

Light weight aluminum has ended up being a favored material in production as a result of its unique combination of residential or commercial properties that enhance performance and performance throughout various applications. Its light-weight nature permits decreased energy usage during transport and assembly, making it an affordable option for lots of markets. Additionally, light weight aluminum shows excellent corrosion resistance, making sure longevity and decreasing upkeep costs.ght ratio makes it possible for the production of durable yet light-weight elements, which is specifically valuable in fields such as auto and aerospace. Light weight aluminum additionally provides exceptional thermal and electric conductivity, making it suitable for a selection of industrial applications, consisting of electronics and warmth exchangers.

Moreover, aluminum's malleability permits elaborate layouts and simple construction, facilitating the manufacturing of complex forms without jeopardizing structural integrity (Aluminum Foundry). These advantages jointly add to aluminum's expanding importance in modern manufacturing processes, driving innovation and boosting item performance throughout a broad variety of industries

Advancements in Light Weight Aluminum Casting Innovation

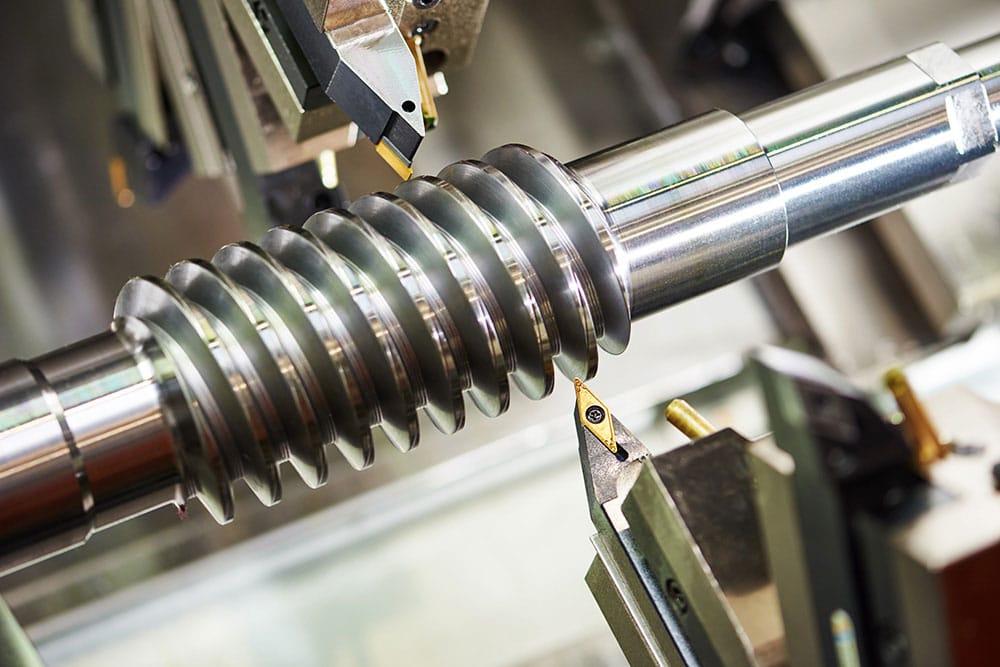

As advancements in making innovation continue to advance, technologies in aluminum casting have actually arised, boosting performance and accuracy in manufacturing processes. Amongst these developments is the intro of innovative simulation software, which enables makers to model the spreading process essentially. This innovation allows the prediction of possible problems and maximizes mold style, inevitably minimizing product waste. In addition, the growth of brand-new alloys has expanded the variety of applications for aluminum castings, improving mechanical residential properties and rust resistance.The fostering of 3D printing for mold and mildew manufacturing has reinvented the spreading procedure, making it possible for the creation of complex geometries that were previously unattainable. This shift not only shortens lead times but additionally assists in personalization in manufacturing. Overall, these technologies add significantly to the quality and versatility of light weight aluminum castings, placing them as an essential element in the future of manufacturing modern technology.

Effect On Production Performance and Expense Decrease

While the innovation of aluminum spreading modern technologies introduces numerous advantages, its most notable effect lies in boosting manufacturing performance and driving expense decrease. By improving the casting process, manufacturers can create complex components with better speed and precision, substantially reducing waste. Innovations such as high-pressure die casting and progressed mold and mildew designs permit quicker cycle times and enhanced dimensional precision, which reduce rework and scrap prices.Additionally, the light-weight nature of aluminum adds to read more reduce transport costs and energy usage throughout production. Consequently, producers can achieve considerable economic situations of scale, inevitably decreasing the per-unit cost of products. The capability to generate premium spreadings in bigger amounts additionally makes it possible for business to respond more quickly to market needs - Aluminum Casting Company. These performance gains and cost savings setting aluminum casting as a competitive advantage in the production landscape, cultivating more financial investments in modern technology and ability growth

Applications of Light Weight Aluminum Casting Throughout Industries

The convenience of light weight aluminum spreading has led to its prevalent adoption throughout different industries, taking advantage of the benefits of lightweight, durable components. In the vehicle industry, light weight aluminum castings are used for engine blocks, transmission housings, and wheels, contributing to sustain efficiency and efficiency. The aerospace industry utilizes light weight aluminum castings for architectural components, where weight decrease is necessary for flight performance. Additionally, the customer electronic devices market leverages light weight aluminum spreading for device real estates and parts, improving resilience while keeping a sleek layout. The building and construction market additionally takes advantage of aluminum spreadings, utilizing them in window frameworks and building elements that call for both strength and visual allure. Furthermore, the clinical area employs aluminum castings for tools and devices, where precision and integrity are paramount. Overall, the diverse applications of light weight aluminum casting across these markets show its important duty in advancing modern-day manufacturing methods.

The Future of Light Weight Aluminum Casting in Production

Development in light weight aluminum casting innovation assures to improve manufacturing processes in the coming years. Breakthroughs such as 3D printing and computer-aided design are enhancing manufacturing, permitting for more complicated geometries and minimized waste. The integration of automation and robotics improves performance, enabling makers to produce top notch components with minimal human treatment. Furthermore, the growth of brand-new light weight aluminum alloys raises strength and sturdiness, broadening the potential applications in fields like aerospace and automotive.As sustainability becomes a priority, recycling capacities within light weight aluminum spreading will certainly enhance, lessening environmental impact. The implementation of smart manufacturing strategies, consisting of IoT and information analytics, will further maximize manufacturing process and maintenance practices. These developments not just enhance operational effectiveness however additionally reduced expenses, making light weight aluminum casting an also extra attractive option for manufacturers. Eventually, the future of light weight aluminum spreading holds pledge for advancement, sustainability, and enhanced competition in the worldwide market.

Frequently Asked Inquiries

What Security Steps Are Associated With Light Weight Aluminum Spreading Processes?

Safety and security procedures in aluminum spreading procedures include safety gear, correct air flow, training on devices use, normal maintenance of machinery, surveillance of molten metal temperatures, and adherence to safety and security procedures to avoid crashes and guarantee employee wellness.

Just How Is Aluminum Spreading Ecologically Sustainable?

Light weight aluminum casting is eco sustainable as a result of its recyclability, power efficiency, and lowered greenhouse gas exhausts. The use of recycled light weight aluminum considerably decreases the power needed for manufacturing, lessening environmental influence while conserving all-natural resources.What Prevail Problems in Light Weight Aluminum Castings?

Common issues in aluminum castings consist of porosity, shrinkage, misruns, chilly shuts, and incorporations. These problems can arise from improper temperature level control, inadequate mold and mildew style, or contamination, impacting the total high quality and integrity of the end product.Can Light Weight Aluminum Casting Be Reused?

Yes, aluminum spreading can be recycled. The reusing process reduces power consumption and ecological effect, permitting the reuse of light weight aluminum in brand-new products. This sustainability aspect enhances its charm in numerous manufacturing markets.What Industries Mostly Make Use Of Aluminum Spreading?

Light weight aluminum spreading is primarily used in the vehicle, aerospace, durable goods, and electronics markets. These markets gain from light weight aluminum's light-weight, corrosion-resistant residential or commercial properties, improving product efficiency, effectiveness, and durability throughout various applications and components.

Over the decades, various innovative methods have transformed aluminum casting, substantially boosting its performance and accuracy. As advancements in manufacturing technology proceed to develop, technologies in aluminum spreading have actually arised, boosting performance and accuracy in production processes. While the development of aluminum spreading modern technologies presents many advantages, its most remarkable influence exists in boosting production performance and driving price decrease. The aerospace industry uses light weight aluminum castings for structural parts, where weight reduction is vital for flight performance. Light weight aluminum casting is eco lasting due to its recyclability, power performance, and lowered greenhouse gas exhausts.

Report this wiki page